Case Study

Overview

Maxstaff.co partnered with an Australian Engineering Company to deliver specialized fabrication and engineering solutions tailored to support their complex requirements for clients in various sectors, including power generation, oil & gas, and air handling systems.

Project Scope and Challenges

The client needed advanced engineering support across several high-precision fabrication projects:

- Sheet Metal Enclosures for Generators

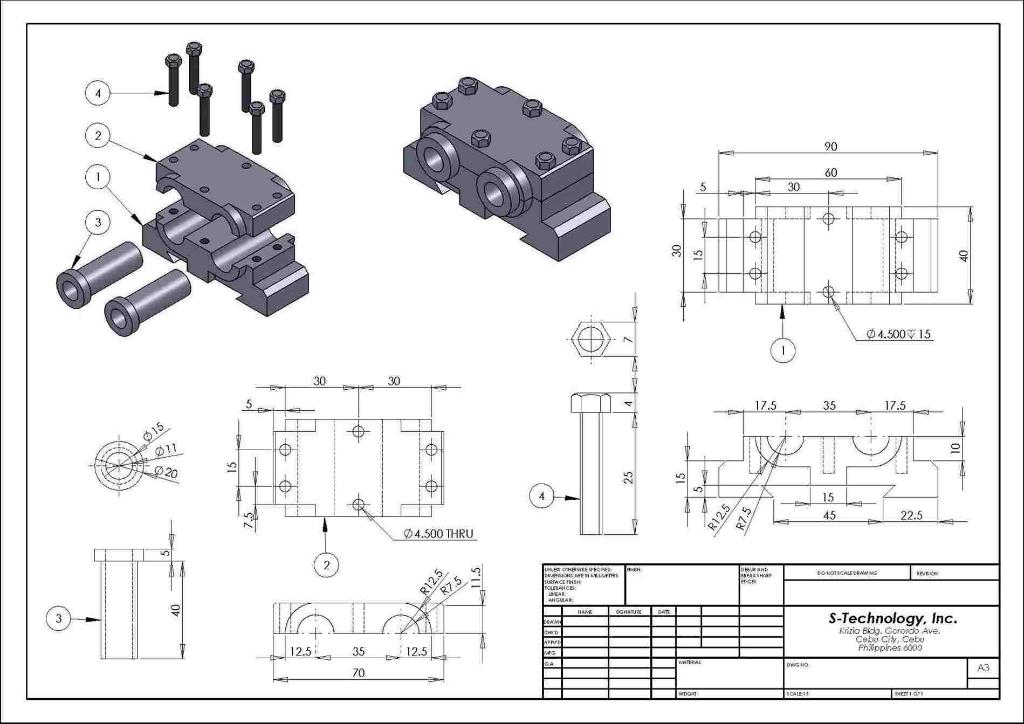

- Scope: Conversion of 2D prints to 3D data and development of sheet metal canopies, fuel tanks, and radiators for diesel and gas generators ranging from 5KVA to 500KVA.

- Deliverables: Detailed general arrangement drawings, fabrication-ready shop drawings, and BOM (Bill of Materials) for accurate and efficient manufacturing.

- Auxiliary and Packaging Systems for Air Filtration

- Scope: Structural design services for air intake filtration systems and related components for applications in air separation, oil & gas, fertilizer, and steel plants.

- Deliverables: Equipment layout drawings, foundation and commissioning drawings, and detailed engineering designs for efficient installation and operation.

- UV Germicidal Irradiation Systems for HVAC

- Scope: Designing UVGI systems compatible with new or existing HVAC setups, focusing on enhancing air quality through UV-based sterilization.

- Deliverables: Part drawings, engineering datasheets, product costing, and certification documentation to ensure compliance with standards.

- Precision Sheet Metal Fabrication for Aerospace and Semiconductor

- Scope: Precise fabrication of sheet metal parts, enclosures, and cabinets for highly regulated industries.

- Deliverables: Comprehensive shop drawings, BOM, and process estimation, providing Barkly Engineering with a full view of manufacturing requirements.

- Detailed Engineering for Boilers and BOP Units

- Scope: Detailed engineering of biomass and multifuel boilers, including structural design and fabrication for plant utility systems.

- Deliverables: Fabrication drawings, piping and support rack details, and assembly support structures essential for plant operation.

Solutions Provided

Maxstaff.co set up a team of Drafters, QA, Project Manager, Estimators and design consultants who utilized a range of software tools, including AutoCAD, SolidWorks, and Inventor, to provide:

- Accurate 2D to 3D Conversions for seamless design adaptation.

- Detailed Engineering Documentation to support fabrication and installation.

- Optimized Material Selection and Sourcing through comprehensive BOMs and vendor specifications.

- Structural Integrity Checks and Compliance ensuring designs met safety and operational standards.

Results

- Enhanced Production Efficiency: Clear, standardized drawings and BOMs enabled the client to streamline their production cycles and reduce potential errors during fabrication.

- Operational Readiness: With foundational and erection drawings, client’s team could swiftly move from design to installation, meeting project timelines effectively.

- Improved Product Quality and Compliance: Maxstaff.co’s thorough design validation process ensured the client’s products met industry standards, particularly critical in regulated sectors like aerospace and oil & gas.

Conclusion

Maxstaff.co’s engineering expertise empowered the client to elevate their production quality and project efficiency. The collaboration highlighted Maxstaff.co’s ability to provide specialized engineering and fabrication support, helping clients achieve both operational excellence and regulatory compliance.

This case study illustrates Maxstaff.co’s commitment to delivering detailed, reliable engineering solutions that address complex manufacturing needs across diverse industries.